|

Shijiazhuang Goodcrete Waterproof Protective Co., Ltd.

|

Deep Penetrating Sealer Professional Manufacturer

| Price: | 3.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Deep Penetrating Sealer Professional Manufacturer, Competitive Price

Deep Penetrating Sealer Professional Manufacturer

Professional Manufacturer, Core Technology!

International First-class Quality, But Competitive Price!

Provide OEM service.

We can provide:

01. OEM Service

02. Product Data Sheet.

03. MSDS

04. Test Reports

05. Construction Guideline

06. Company Brochure

07. Powerpoint(PPT)

Introduction:

Goodcrete Deep Penetrating Sealer(DPS) is a silicate-based, inorganic, nano grade, penetrating and crystallization waterproofing&protective agent for concrete construction, it is environment friendly, colorless, odorless, non-toxic, non-flammable, easy and safe to use. Beside durable waterproof and anti-seepage functions, it also can give the concrete construction comprehensive improvement and protection, such as self-sealing, waterproofing, moistureproofing, anti-seepage, anti-efflorescence,anti-corrosion, anti-chloride, etc.

History of Deep Penetrating Sealer:

Deep Penetrating Sealer was used in the America as early as 1940s, mainly used for the waterproofing and

moisture proofing etc of underground bunkers during the Second World War, and now, it is already widely used in so many countries for so many projects.

Working Principle:

The inner alkali content of the concrete is about 360 times more than the surface's, through the pores, DPS penetrates into the concrete structures, chemically reacts with the free alkalis presented in the concrete and forms silicate gel, which seals the micro cracks and capillary pores becomes the integral part of the concrete, strengthens the concrete structure, and blocks the harmful substances ingress; when water losses, it partly solidifies into crystalline powder, let the concrete breathe freely, when meets with moisture or water, this reaction repeats again, thus, gives the concrete permanent waterproofing and protection, such as sealing, waterproofing, anti-permeating, hardening, dust-proofing, anti-corrosion etc.

(Fibre like crystals formed by the crystallization-test of Goodcrete DPS and baking soda.)

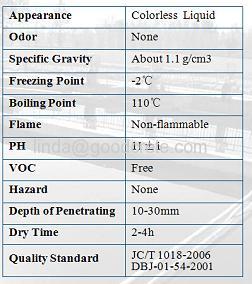

Product Data:

Characteristics and Functions:

01. Permanent waterproofing, moisture-proofing and anti-seepage;

02. Reinforces the density and hardness of concrete;

03. Reduces dusting, efflorescence, cracking and damage of freeze/thaw cycles;

04. Self-seals hairline cracks <<0.3mm repeatedly;

05. Resists the corrosion of chloride, UV, chemicals and salts;

06. Discourages the growth of bacteria, mold and microorganism;

07. Prolongs the service life of paint and concrete buildings.

08. Not changes the color and structure of the substrate.

10. Non-toxic, absolutely environment friendly.

11. Easy and fast to use, spray, brush or roll evenly on the surface.

12. Rigid waterproofing, doesn't need screed-coat and protective coat;

13. Inorganic products, permanent functions.

Recommended Applications:

Waterproofing Moisture-proofing Anti-permeating | Basement, subway, sewage treatment plant, dam, reservoir,various pools, dock, green roof, grain depot, warehouse, civil air defense construction, floor's waterproof layer, etc. |

Dust-proofing Anti-microorganism Anti-pollution | Clean workshop, winery, food factory, grain depot, ancientarchitectures, etc. |

Anti-acid/alkali/salt | Chemical plant, waste yard, power plant etc. |

Structure Reinforcement Anti-cracking Reduce freeze/thaw damage Prolong service life | Bridge and culvert, airport runway, parking lot, tunnel, etc. |

Improve adhesion Prevent finish coating peel off | Concrete cracks/damage repair; As primer coating of finish coating, etc. |

How to use:

01. Equipment: Broom, respirator, low pressure sprayer (or brush, roller), gloves, work clothes and boots, etc.

02. Visible cracks ≥0.3mm, should be repaired first.

03. Thoroughly clean up the surface, thoroughly remove contamination, laitance, oil, film and coating to ensure the DPS can efficiently penetrate into the surface..

04. The surface should be dry or semi-wet.

05. Shake well before using.

06. Spray the DPS evenly and saturatedly on the clean concrete surface, the areas become dry too quickly, immediately spray again.

07. Coverage: 3-5 m2/kg(2 times spraying), the higher the substrate density, the less spraying quantity.

08. Air temperature 5-35℃, surface temperature 2-33 ℃, relativehumidity 10-90% is the best.

09. When the whole surface become semi-wet after the 1st time spraying, spray DPS for the 2nd time.

10. Avoid the surface suffering from water and rain within 24h after construction, and after 3-7days, the treated surface can be started following works.

Packing: 20KG/ Pail, 220KG/Pail i.e. 5 US Gal/Pail, 55 US Gal/Pail(HDPE Pail)

Skype: goodcrete